As an example of the effectiveness of the feasibility of the technical and technological audit is not a large-scale crushed stone quarry with an annual capacity of up to 1 million. tons per year.

As part of the feasibility study in accordance with the technical project the following works were carried out:

– determining the presence of the potential for improving the efficiency and reducing the cost of mining and transport operations in the mining and accepted technical, geological, Mining and geometric, organizational and economic conditions;

– assessment of opportunities and ways to increase the effectiveness of the production

assignments;

– assess the effectiveness of mining and transport equipment, expedient quantitative fleet;

– determination of directions of changes in production organization in order to ensure that the technological and economic indicators;

– give advice technical and organizational measures to reduce the cost of mining and transport operations;

– estimate the amount and timing of investments to achieve this goal.

Performance Analysis of an industrial complex career for the four months from May to August inclusive, showed, that during this period of 242 calendar shift worked Production Complex 167, or 69% work shifts. The most frequently obtained from the performance of 1500-2000 tonnes, and the average for the period - 1942,0 tons / shift. In the following analysis, this option was adopted for the base.

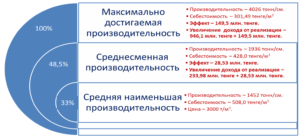

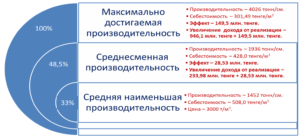

The analysis according to the basic embodiment of the mining and transport complex showed career, in mining and technical data, Mining and geometric, geological, organizational and economic conditions of its monthly and annual performance can be respectively 116,5 thousand. tons and 832,2 thousand. tonnes. these indicators in the implementation of the most efficient mode of operation of the main process equipment may be respectively 240,0 thousand. tons and 1920,0 thousand. tonnes. In fact, performance is achieved at the level of, respectively, 80,4 thousand. tons / month. and 643,1 thousand. tons / year or 30% of the maximum possible data

conditions of.

Visual observation of the work of the dump, as well as information dump drivers exceeding the carrying capacity of the passport can be 20-30% and more (to 28-35 tonnes), which leads to a significant increase in fuel consumption and, ultimately, the cost of mining and transport operations.

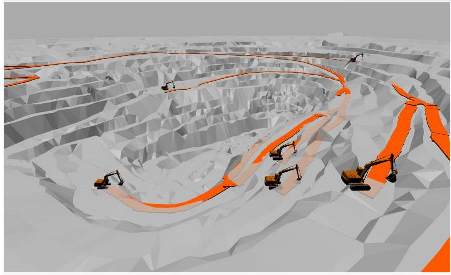

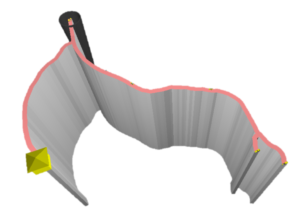

The structure of the scheme of highway, received information using the interface software and Methodology complex IPMK "SEBADAN-AUTO", is shown in Figure 1. When forming the pattern of actual highway completely reproduced the structure and geometry of the road, including angles at each of its flow stations.

rice. 1. - Model motorway career

On the model reproduced in fact adopted by the organization of the work of mining and transport complex. The highway is divided into

block portions due to their geometric and functional characteristics (to remove, on the horizon, bottomhole site, unloading standby site, weighing station and passing technical inspection).

In order to adequately assess the effectiveness of the technical and economic policy at the enterprise in the course of the study used the approach of the economy of process management geotechnological complex. The approach involves a qualitative consideration of operational costs of the mining and transportation process, including consideration of real wages of drivers and drivers of dump trucks loading equipment, age and the residual value of mining and transport equipment,

depreciation on equipment and transport communications, expenses, Related energoraskhodom, as well as additional costs. Since the company account operating costs virtually absent, In addition to fixed salary operators of mining and transport complex, techno-economic analysis was performed using accurate simulation model of mining and transportation process to career.

The analysis identified the potential and the different ways to increase the production efficiency of mining operations on the deposit based on the technical operation requirements and technological standards.

The main directions of improving the efficiency of the mining and quarry transport system were determined by the results of the feasibility study and organization affect the mining and transport operations, selection of main process equipment, optimization of modes and conditions of its operation.

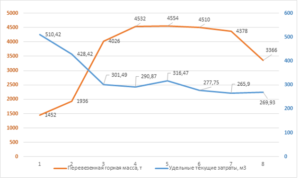

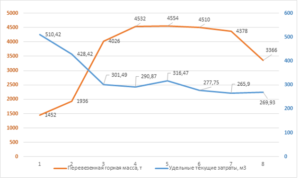

On the organization of mining and transport operations in the framework of research on the simulation model of mining and transport complex simulated four possible scenarios for the development of mining and transport operations. As the first embodiment discussed with capacity of up to 1500 tons / cm. In the first version of mean-shift the cost of mining and transport operations made 510,42 tenge per m3.

The second option was adopted by the mean-shift annual output, which is most similar in meaning to the model were 1936 tonnes. In this case, the improvement in the mining and transport complex achieved only by increasing the time of operation of the crusher. Unit cost of mining and transport operations made 428 tenge per m3. In this case, for

by reducing the cost of mining and transport operations and the increase of output to the crushing economic effect was 28,53 million. tenge. In the case of the annual volume of rubble produced at a price 3 thousand tenge per cubic meter.

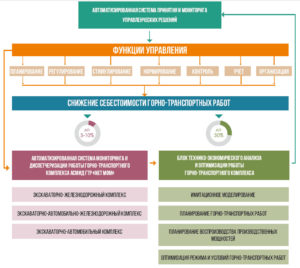

increase the company's revenue may reach 233,98 million. tenge, and taking into account the economic effect of reducing the cost of mining and transportation of works overall economic effect can reach 262,56 million. tenge / year, as shown in Figure 2. The third version of the work of mining and transport complex at the maximum reached on the fact

shift productivity during the period, that model was 4026 tons / cm. In this case, the unit cost of mining and transportation of works was 301,49 tenge per m3. According to calculations similar, to assess the cost-effectiveness, in this embodiment, it may reach income 946,1 million. tenge, by reducing the cost of mining-

transport operations - 149,5 million. tenge / year, and in the general economic benefit can reach 1037,98 million. tenge / year.

The fourth version of the work of mining and transport complex was adopted on the basis of passport work equally crusher 4500 tons / cm. When this was in fact achieved in the model performance 4532 tons / cm (1697,4 m3 / cm), and specific indicator cost of mining and transport operations is becoming 290,87 tenge / m3. In this way, at level performance mining and transport complex, equal performance rating crushing and screening

complex economic effect of reduced

rice. 2 . - Comparative efficiency of the mining and transport complex of the basic variant

the cost of mining and transport operations may reach 112,07 million. tenge / year, and increase the overall profitability of the enterprise rises to 1178,1 million. tenge / year. Then, the overall effect can achieve 1290,17 million. tenge / year.

The main conclusion of the four options listed mining and transport work is, without changes in the structure and organization of mining and transport operations, only while ensuring appropriate operation crushing plant, can provide an increase in productivity is nearly three times with reduced cost

mining and transport operations on 60% and more, with economic benefit to 150 million. tenge / year or more. When the maximum rating performance DSC overall effect can reach 1290,17 million. tenge / year at an average

the cost of gravel at 3000 tenge / m3.

As part of the optimization of the number of the working park dump accepted model were modeled ceteris paribus versions with dump trucks of between 3 to 7 machines. The productivity of mining and transport of the complex were respectively 3366, 4378, 4510 and 4554 tons per shift, as shown in the diagram of the figure 3.

From the diagram it follows, that the minimum value of the index of unit costs of mining and transport operations while maintaining the performance of the mining and transport complex at the level of the rating performance of DSC

(option 6 - with 5 dump) is 277,75 tenge / m3. In this case, the maximum economic benefit from reducing the cost of mining and transportation of works will be 122,16 million. tenge / year, Income from sales - 1167,99 million. tenge, and overall efficiency - 1290,15 million. tenge / year.

As the results, in this series will be most effective and optimal in terms of the cost of mining and transportation of works is an option 7 (with 4-dump trucks), wherein the minimum value is provided by the indicator unit current at costs 265,9 tenge / m3. but,taking into account the reduction of the optimal value of the performance of mining and transport complex to 4378 tons / cm, economic efficiency by reducing the cost of mining and transport works in this case is 127,91 million. tenge, the yield from the increased volume - 1107,48, and the overall economic effect - 1120,19 million. tenge / year, significantly inferior to the two previous options.

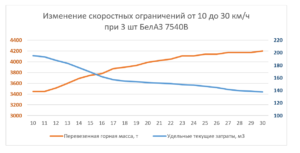

Generally, largest total economic impact, among eight options for mining and transport operations in the existing conditions, as well as the number of total available fleet scheduling, It is the most appropriate variant 6 at an operating park dump strength 5 PC. By the choice of mining and transport equipment is one of the ways to increase efficiency and reduce costs associated with the selection of the most suitable for data

conditions of mining and transport equipment, as well as with the definition of optimum number. We consider the most probable range of variation in the various specific and operating costs and performance at a given

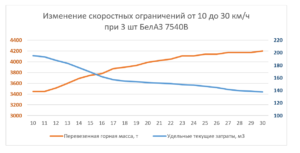

mining and transport complex is determined by the most economically viable. Data mining and technical conditions,

the most likely alternative is career dump load capacity BelAZ-7540V 30 tonnes. He is at a higher cost significantly lower fuel consumption and greater shelf life for use in such conditions. In this series of studies, at a similar rate in the load direction and porozhnyakovom, of equal 10 km / h, discusses embodiments respectively using 3, 4 and 5 dump, under List the amount equal to the park 5 machines. As the analysis of the results according to the embodiments, It is the most appropriate option from the four dump trucks working in the park. When this capacity is 4500 tons / cm, which corresponds to the rating

performance DSK. Unit operating costs of mining and transport operations in this embodiment constitute 176,12 tenge / m3

, What's on 79 tenge less best mode working with dump Hovo mark or 101,63 tenge less expedient embodiment at most 6 dump trucks Hovo. This ensures that the economic effect of reducing the cost of

at the level 82,22 million. tenge / year compared with the best option, and 204,1 million. tenge / year compared with the mean-shift option during the study period. The main factor in reducing the cost of mining and transport operations is the fuel consumption, which specific indicators on TCM below 5 or more times.

According to the modes and conditions of operation of mining and transport complex career discusses various speed modes and conditions for major mining and transport equipment. Vary the quality of road surface and the speed limit at the appropriate one-time and ongoing operating costs. According to this criterion

defined variant with the most optimum parameters. The first option considered primed with neukatannym expensive with regard to the relevant non-recurring and ongoing operating costs. This sets the optimal speed limit mark dump BelAZ-7540V for trucks and porozhnyakovogo directions

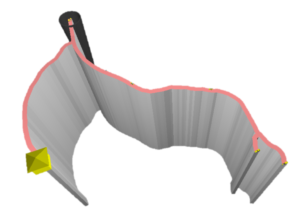

respectively 15, 20 and 25 km / h when the number of vehicles, consecutively equal 3, 4 and 5 PC. The results of this series of simulations embodiment partially shown in a diagram in Figure 4.

rice. 4. Option with a working fleet of dump number three cars

The data presented, what, in the case of operation of dump BelAZ-7540V when the speed limits to 30 km / h, the most cost-effective option when four cars, performance when mining and transport complex may reach 5400 tons / cm at the cost of mining and transport operations, equal to just over 120 tenge / m3. but,

in connection with the rating and performance of DSC based on the maximum achieved upon performance, of equal 4500 tons / cm, It will be most feasible option for three dump trucks at a level of productivity 4200 tons / cm and specific current costs for rock mass - 142 tenge, which is less than the average actual cost to 286 tenge. In this case, the payroll car park should consist of four cars of this brand. Economical effect of reducing the cost of mining and transport operations in this case can reach values in 215 million. tenge per year, and the total yield is increased by 1038 million. tenge. In this way, the overall economic effect can make possible 1253 million. KZT year.

NCGT.kz

NCGT.kz